2004 Omga *******************T521 OPT 6000 "US" used Optimizing Saw #BM2169

2004 Omga *******************T521 OPT 6000 "US" used Optimizing Saw #BM2169

Location:Ontario, Canada

Description

REDUCED PRICE!

Automatic programmable Optimizing cut-off saw for precision length cutting of wood stock.

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

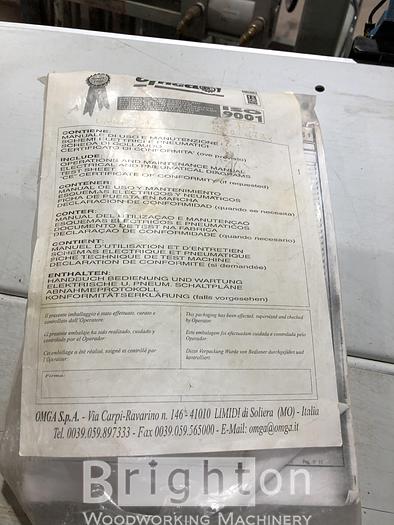

| Manufacturer | Omga |

| Model | *******************T521 OPT 6000 "US" used Optimizing Saw |

| Year | 2004 |

| Condition | Used |

| Stock Number | BM2169 |

| Quality | Very Good |

| Electrics | 208V / 3 Ph / 60 Hz |

| Weight | kg |

| Note: | Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!! |

| * | All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. |

Additional Features

**Info taken from same model found online. Interested buyers should verify all information before purchasing.**

20 ft capacity!

Automatic programmable cut off saw for defecting and optimised cutting.

Cutting line composed by a 4 or 6 meters useful length pusher. The pusher carriage is complete with a laser system for reading the length of the board and marking the defects to be cut out.

Cut off saw blade diameter 500 mm.

Allows strict tolerances on the cut length (+/- 0,5 mm on the standard version, +/- 0,2 mm with precision magnetic tape).

The scanning of the board before introducing it into the machine made by the laser system allows to reach a full optimization and to cut defects without staining the board. The 10° tilt angle of the line ensures the correct positioning of the material against the fence, while the perfect holding of the piece during the cutting cycle is ensured by a vertical pneumatic clamp.

On request the cutting line can be completed with tables or rollers at the out-feed, simple sorting systems, pneumatic gripper for a perfect holding of the piece during the feeding and front clamps.