2016 Felder Profit H200 used Pod and Rail CNC machine #BBM2158

2016 Felder Profit H200 used Pod and Rail CNC machine #BBM2158

Location:Ontario, Canada

Description

- Small footprint – minimal space requirement!

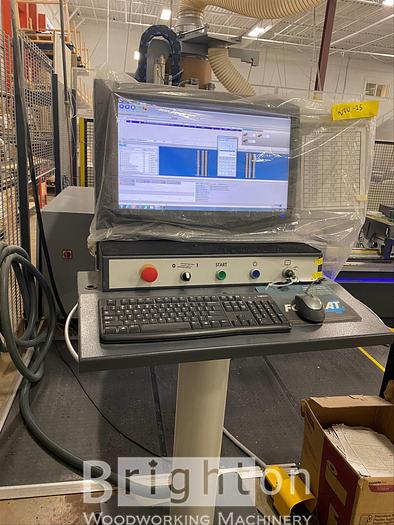

- Drawing = programming, intuitive operating software

- Software including 3D cabinet software “F4-Design” for presentation, parts list and connection to the machine

- Gantry design, solid construction for maximum performance

- The drilling head covers the whole working field

- High quality dual circuit vacuum clamping system with 100 mm vacuum pod height

- F4®Solutionsready

Specifications

| Manufacturer | Felder |

| Model | Profit H200 used Pod and Rail CNC machine |

| Year | 2016 |

| Condition | Used |

| Stock Number | BBM2158 |

| Quality | Very Good |

| Electrics | voltage to be confirmed / 3 Ph / 60 Hz |

| Note: | Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!! |

| * | All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. |

Additional Features

***FOR COMPLETE DETAILS PLEASE SEE ATTACHED DOC BELOW: ***

THIS CNC WAS PURCHASED IN 2018.

Felder Profit H200 used Pod and Rail CNC machine.

Working field H200 13.33:

Travel distance of the axis:

X= 4000 mm

Y= 1670 mm

Z= 500 mm

"Working area: X= 3300 mm

Y= 1280 mm"

Z= 250 mm passage height (from the level of

the consoles), depending on the clamping

system, see layout.

15 KW (S6) main spindle HSK F63 24,000 rpm, ceramic bearings with pneumatic height adjustment of the extraction hood to 2 positions:

Power requirement: 15 kW ( S6 )

Full power capacity at approx. 12,000rpm Rotating speed: 1000 - 24000 rpm

Drive: 3-phase HF motor, inverter controlled rotation: left/right,

2 controlled compressed air connections, interface for aggregates ,

Tool weight (rotating): 7.5kg.

X-axis guiding system:

The drive of the gantry along the X axis is

carried out using a rail with angled,

cambered teeth. This guarantees maximum

precision.

The reduction gearing ensures maximum

processing quality and repeatability.

Positioning is carried out by recirculating

ball bearings running along

hardened and polished linear guides.

"Y-axis guiding system:

Positioning is carried out by recirculating"

ball bearings running along

"hardened and polished linear guides.

The Y axis is positioned by a polished"

recirculating ball spindle .

Guiding system Z-axis:

Positioning is carried out by recirculating

ball bearings running along

hardened and polished linear guides.

The Z axis is positioned by a polished

recirculating ball spindle.

The lubrication is applied as and when

required to the guide carriages of the X, Y

and Z axis as well as the bearing spindles

in Y and Z. Lubrication is carried out

automatically after a preset time.

DH16 4H 2S drilling head:

12 vertical spindles

7 spindles in X direction and 5 spindles in

Y direction. 4 horizontal spindles :

2 spindles in X direction and 2 spindles in

Y direction. Prelift = 70 mm, max. drill

length = 70 mm and shaft D = 10 mm.

All spindles can be used independently of

the others.

2 grooving saws - one each in X and Y

direction, max. saw blade diameter 120 mm,

max. blade thickness 5 mm, max. speed

variable up to 7500 rpm. The drilling head

covers the whole working field, with both

the horizontal and vertical drills.

Centrally controlled extraction connection:

The program control controls the extraction

to either the drilling head or main spindle.

The controlled gate ensures an optimum

extraction performance.

Connection diameter see layout.

Positioning display of consoles

and vacuum pods:

The workpiece, the consoles and

the vacuum pods are all shown in the

CNC Board simultaneously. This guarantees

that the workpiece is positioned securely

and that there can be no collision

between the tooling and vacuum pods.

The exact position of the vacuum pods on

the console is displayed using a laser.

Vacuum connection for template milling

on the left hand side of the machine.

Vacuum system 90m3/h:

1 vacuum pump with a total vacuum capacity

of 90 m3/h I 50 Hz, 108 m3/h / 60 Hz.