2020 Biesse Rover K FT 1224 Used 4 x 8 Flat table CNC #BM2704

2020 Biesse Rover K FT 1224 Used 4 x 8 Flat table CNC #BM2704

Location:Uxbridge, Canada

Description

2020 Biesse Rover K FT 1224 Used 4 x 8 Flat table CNC

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information

Click <SHIP> for shipping information.

Specifications

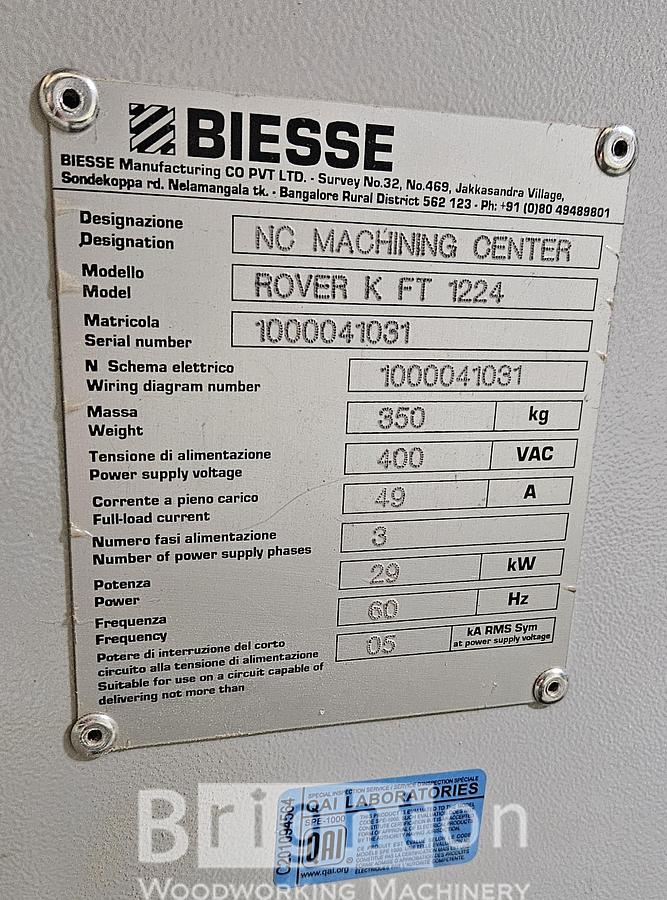

| Manufacturer | Biesse |

| Model | Rover K FT 1224 Used 4 x 8 Flat table CNC |

| Year | 2020 |

| Condition | Used |

| Serial Number | 1000041031 |

| Stock Number | BM2704 |

| Quality | Very Good |

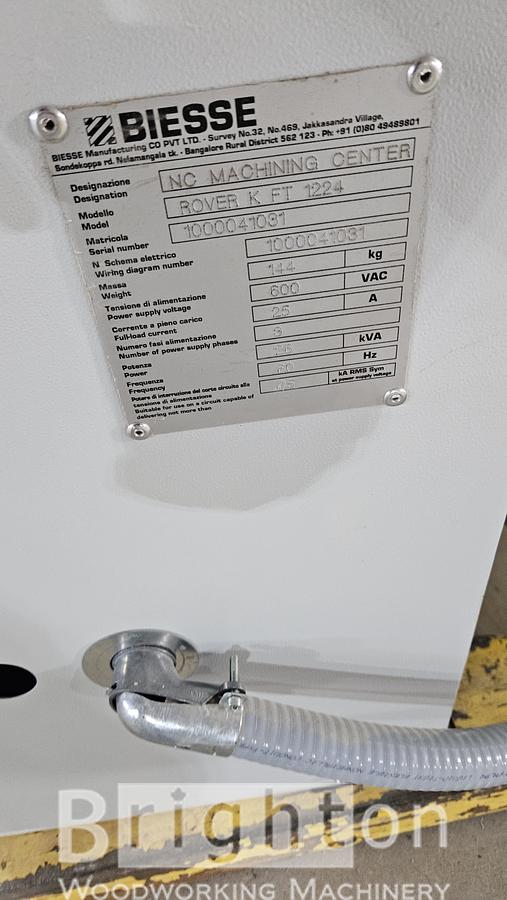

| Electrics | 600V / 3Ph / 60 Hz with included transformer |

Additional Features

Purchased in 2021 and used in a very small shop in Ontario. Like new.

Features include:

Highlights:

HSD 12 Hp HSK F63 electrospindle

FT worktable dimension: X=2463 mm; Y=1258 mm (4ft x8ft).

Table Sweeper Arm on gantry.

Air condition control cabinet.

10 position tool changer

10 spindle vertical drill block

Tool Touch off device for cutting depth

Automatic lubrication of guideways

Helical rack and pinion drive on X

Precision ground screw on Y and Z axis

Additional Z axis plate for drill block

170mm (6.7") maximum Z axis capacity

60m/min rapid traverse speed

CNC controlled dust ports for the router and drill block

CNC controlled sweep with integrated dust collection

21" screen controller with Windows 10

Mouse and Keyboard

B-solid CAD/CAM with BNest (1 seat)

Auto transformer

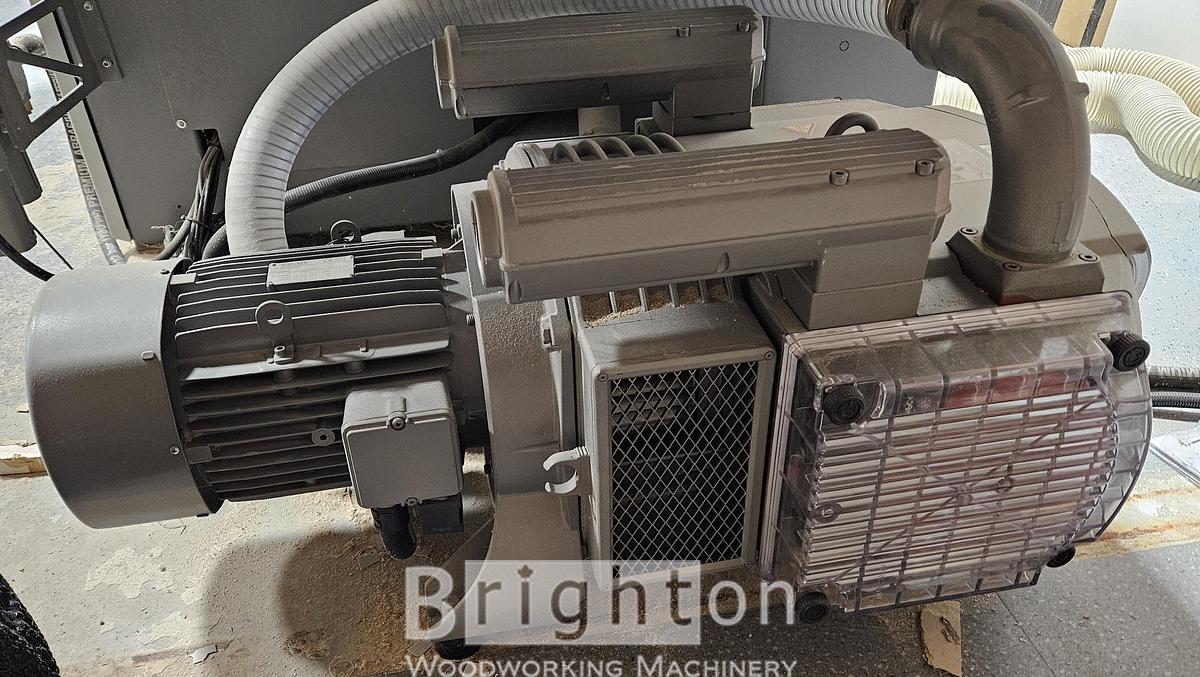

250 M3/hr vacuum pump

MORE DETAILED SPECS:

Structure

Biesse design is based on a CAD product for solid modelling which allows to determine the possible structural distortions caused by static and dynamic loads and to dimension the most critical components, highlightening the most stressed areas which need strengthening_ ...--

Machine frame

The machine frame is made of thick electro-welded steel with a closed ring structure, properly strengthened in the most stressed areas.

P" Upright beam

The upright beam, mobile in the longitudinal direction (X axis) is made of electro-welded steel with gantry structure: thick steel sheets and reinforcing transversal elements grants a higher rigidity and allow to obtain the maximum accuracy.

Transversal and vertical carriages

The transversal carriage (Y axis) and the vertical carriage (Zaxis) are made of an aluminium light alloy casting which is stabilized and then machined in a single setup for maximum precision.

Control system

Numerical Control

Biesse property BH660 control system is PC based.

The new Biesse technology WRT {Windows Real Time) extends the functionalities of Windows operative system by making it work in real time and able to directly control the machine avoiding not necessary hardware and increasing reliability and performance.

*1 Desktop Personal Computer

Main technical specifications:

CPU lntel(R) Core i5 or superior

8 GB RAM memory

128 GB (SSHD) hard disk or superior

Dedicated graphic card

21.5" LCD

Keyboard

Mouse

USB ports

Ethernet card for network connection to an office PC

Technical specifications

Maximum axes speed X - Y - Z: 25 • 25 • 25 m/min

Z axis stroke 320 mm

Z axis piece passage 170 mm

*Z axis piece passage with Sweeper Arm 170 mm

* The technical data shall be verified on detailed layout according to the operating units chosen on the machine

Numerically controlled machining center ROVER K FT 1224

FT worktable dimension: X=2463 mm; Y=1258 mm

bTouch-Touch screen monitor

bTouch, in synergy with the interface bSuite 3.0 (or later), optimized for touch use, guarantees to fully exploit the functions of BIESSE software.

This solution provides a simple and intuitive use of the software installed in the machine. The touch screen replaces the functions of the mouse and keyboard, guaranteeing direct interactivity between user and device.

In particular, it is possible to:

- Create any CAD program (also parametric) including geometry and machining;

- Zoom. move and rotate objects (piece, CNC, tools, etc.) present in the CAD/CAM area;

- Equip the magazines simply by dragging the tools in the slot assigned;

rt Prepare the machine for the correct positioning of the workpiece (machine set-up) by shifting panel supports and sliding bases to the desired position;

Send a work fist, change the parameters and send it to the NC for further processing;

- Manage all the commands in soft-console.

Technical specifications of the touch screen:

- Display: 21.5" 16:9;

- Maximum resolution:1920 x 1080 (Full HD) to 60 Hz;

* Requires bSuite 3.0 or later

C4000148

Automatic lubrication system

At each set time interval, adjustable in the numerical control, the pump automatically sends the lubricant to the machine moving parts (linear guides and bearings, recirculating ball screws), with no machine downtime and no operator's intervention.

When the quantity of lubricant in the tank reaches the minimum, a warning message appears on the N.C.screen.

* Requires ISO or HSK electrospindle

C4000219

Autotransfonner for voltages different from 380-40D-415V at 50-60Hz

Allows the machine to be connected to the power supply with a voltage different from 380-400-415 at 50-60Hz Compatible voltages: 200V - 220V - 230V - 240V - 440V - 460V - 480V - 575V- 600V at 50-60Hz

C7210005

9.0 kW (12 HP) electro spindle with HSK F63 coupling, air cooled

Technical "specification:

-Ceramic bearings

-Rh and Lh rotation

- 7,5 kW (10 HP) from 12,000 to 15.000 rpm in S1 duty

- 9,0 kW ( ) from 12,000 to 15,000 rpm in ty

- Rotation speed from 1000 TO 24000 rpm, programmable by N.C.

C7022025

Boring head BH 10

Working unit which can be equipped with 1O independent tools for single and multiple borings on the top face of the panel.

The spindles have a RH/LH alternated rotation and are driven by precision helical ground teeth gears which grants minimum noise emission and maximum machining accuracy.

The boring head is equipped with a manual lubrication system to be performed at a set time through the greasing pump, and it's reminded by a warning message on the N.C. screen.

BSolid

3D CAD-CAM program to design, simulate and manage the machining processes of the Biesse machining centers and boring machines. The use of additional optional modules allows to expand and specialize the performance of the bSolid base module whether it is installed in the machine or in the office.

The software package running in Windows environment allows designing the final product, defining its machining, defining working table set-up, simulating the part machining on the 3D machine model and generating the machine needed programs.

CAD design and project:

-Commands for defining and editing parametric objects such as geometries, surfaces and texts.

-Commands for generating and modifying vertical, inclined and curved custom parametric faces.

- Non- parametric commands dedicated to the modification of geometries, surfaces and texts, such as:

displacement, wheel, scale, symmetrical copy, trim, automatic fillet, union, etc.

- Manual dimensioning tools.

- Environment for inserting and modifying variables, using geometries, surfaces and all processes.

- Design visualization tools such as: zoom, view rotation, orthogonal view on customized faces.

- DXF (Technologic DXF), CIX, BPP, BMP, PNT, DAT, ICP file import.

bNest allows to create nesting projects including the item list with related quantities to be produced and the list of boards to be used with the target of minimize the used material and the machining timings. The optimization process result is a list of bSolid programs (.bSolid) containing all the machining of parts positioned inside the used boards.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. Buyer is responsible to make sure all local regulations for installation and use are followed for area in which it is being installed. Govenment regulations may differ, depending on location.