2016 Homag Brandt KDF 440C, Used Edgebander

2016 Homag Brandt KDF 440C, Used Edgebander

Location:Uxbridge, Canada

Description

Used Edgebander,

Homag Brandt KDF 440C edgebander with Riepe, pre-milling, corner rounding and much more!

"note: click REQUEST QUOTE anywhere you see it on our site to receive an instant auto-quote directly to your email!!"

Specifications

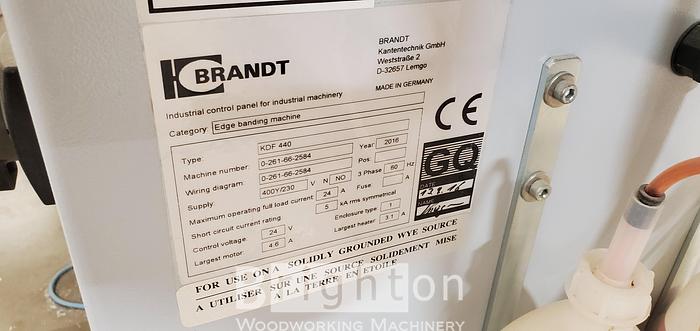

| Manufacturer | Homag |

| Model | Brandt KDF 440C, Used Edgebander |

| Year | 2016 |

| Condition | Used |

| Serial Number | 0-261-66-2584 |

| Stock Number | BM2034 |

| Quality | Very Good |

| Electrics | 600 with included transformer. |

| Weight | approx 4000 lbs |

| * | All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. |

Additional Features

Used Edgebander,

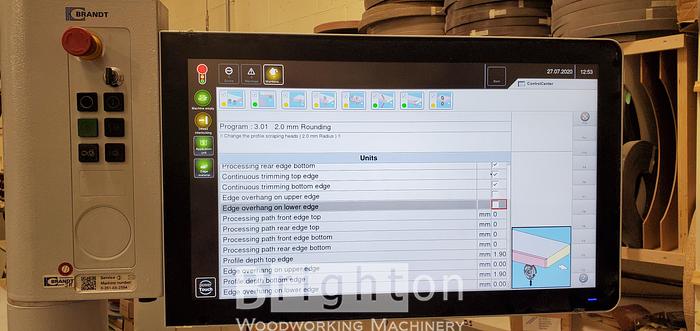

BRANDT - KDF-440C ... Edgebander (w/Pre-Milling & Corner Rounding, with HIGHFLEX Automated package: -- Edge & Workpiece Capacity:0.4 - 8 mm (0.016 - 5/16") edge; 8 - 60 mm (5/16 - 2-3/8") panel thickness; 160 mm (6-3/8") min. panel length and 70 mm (2-3/4") min. panel width.Equipped with: -- Pre-Milling Station, (2) motors @ 2.25 kW (3.0 HP), 12.000 RPM, LH & RH rotation w/pneumatic jump control for chip-free and clean panel edges. Equipped with diamond cutter heads -- In-feed Fence, with servo motor positioning. -- Infrared Radiant Quartz Heating Unit between glue roller and pressure section. -- Automatic Edge Magazine, for strip & coil stock, strips 0.4 mm - 8 mm (0.016 - 5/16"), coils up to 3 mm PVC and "HD" guillotine. -- "Quick Change" Glue Tank for maintenance & glue color change. -- Pressure Section, 1st. roller driven plus (3) idle rollers, timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover. -- Feed Speed, variable 8 - 14 MPM. (26 - 46 FPM), 11 MPM (36 FPM) when using contour trimming. -- BRANDT "Power Touch Control, Memory: 256 MB Ram, 1 GB Flash Card Drive, Operator control panel w/22" color HD wide screen, soft keypad & internal modem for remote diagnostic link.Workstations: -- End Trimming: -- (2) Motor @ 0.35 kW (1/2 HP) 12,000 RPM, automatic chamfer from control panel 0°- 15°. -- Flush/Bevel-Fine/Radius Trimming Unit: Top/bottom (2) motors, 0.55 kW (3/4 HP) 12,000 RPM, auto tilt postioning 0° - 25°, with combination flush/radius/chamfer cutterheads; horizontal and vertical tracing wheels, equipped with brushless multi-axis Servo motors for positioning of work-unit & horizontal copy wheels for quick changeover. Includes (3) positioning options, profile 1, profile 2, and flush trimming. -- Corner Rounding Unit:(1) Motor 0.35 kW (1/2 HP) 12,000 RPM for leading & trailing edges vertical corner rounding of panels; either radius or chamfer cutters can be mounted; 3 mm max. edge thickness. -- Scraping, Multi-Profile (PVC):Top/bottom with (2) profiles. 1 mm and 2 mm or 3 mm instead of 2 mm, servo control positioning of vertical & horizontal copy wheels. PVC scrape collection box. -- Scraping Glue Unit:Flush top/bottom on panel surface with floating insert knives. -- Buffing Unit: Top/bottom (2) motors, 0.10 kW (0.125 HP) 2,800 RPM. -- Riepe anti- adhesion. -- Riepe detergent. Complete with:Motorized, programmable hold-down pressure beam; padded sound enclosure, used tooling and Original Factory machine documentation. -- Actual Model is BRANDT, OPTIMAT KDF 440C (corner rounding).