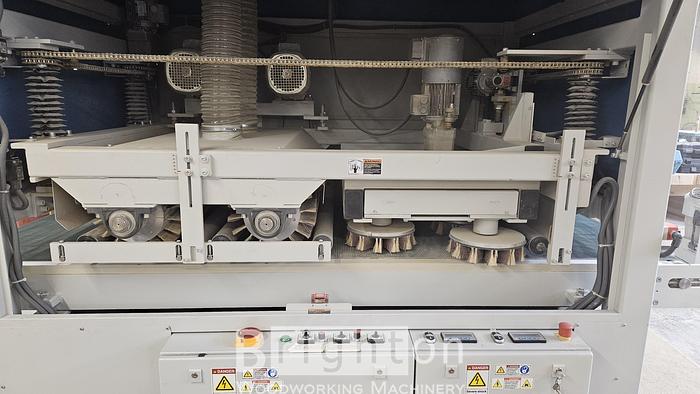

2011 Loewer Discmaster 2DBB Compact used finish brush sander #BM2664

2011 Loewer Discmaster 2DBB Compact used finish brush sander #BM2664

Location:Uxbridge, Canada

Description

2011 Loewer Discmaster 2DBB Compact used finish brush sander

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information

Click <SHIP> for shipping information.

Specifications

| Manufacturer | Loewer |

| Model | Discmaster 2DBB Compact used finish brush sander |

| Year | 2011 |

| Condition | Used |

| Stock Number | BM2664 |

| Quality | Very Good |

| Electrics | 600V / 3Ph / 60 Hz with included transformer. (machine is 480 volt) |

Additional Features

(See details specs below)

The versatile, multi-functional DiscMaster models offer state-of-the-art technology for sanding and denibbing flat and profiled parts. Featuring the excenter disc technology patented by Löwer, the DiscMaster provides unbeatable sanding results making it the number one choice for the discerning customer.

The DiscMaster can be used for white wood sanding, denibbing or interim sanding between coats and is ideal for processing solid wood or MDF doors, shutter frames or other profiled parts.

The discs are equipped with sanding strips and rotate excentrically, sanding the workpiece from all angles and directions. Due to the large contact area, the sanding intensity is much greater , making it also suitable white wood sanding.

Large spiral brush sanding drums are used for refining the surface or for sanding linear profiles. These units come in counter-rotating pairs.

Standard Features:

7 special eccentric orbital discs for a random orbital effect.

2 rows of discs for longer sanding time.

2 counterrotating sanding rollers.

Automatic pneumatically controlled centering of feed belt.

Motorized height adjustment of sanding unit (constant height of through feed).

Separate motorized height adjustment of disc-station independent of sanding rollers.

Electronic digital display of height.

Sensor controlled oscillating blowing device for cleaning work piece.

Antistatic brush strips.

Selection switch for manual mode / automatic line mode.

Specifications:

Max. working width: 900 mm, 36”.

Max. thickness of workpiece: 100 mm, 4”.

Motor disc station: 1 x 1,5 kW, 50-350 RPM.

Motor sanding roller: 2 x 1,5 kW, 100-500 RPM.

Diameter sanding roller: max. 300 mm max., 12”.

Speed of feed belt: 3-15 m/min, 9 – 50 ft/min.

Length/width: 2500 mm/1500 mm, 99 “ / 60”.

Connection dimension: 2 ports at 140 mm.

Operating pressure 6 – 8 bars.

Air requirement: 6 BAR.

Fusing by Customer: 30 A.

Weight of machine: 1 790 kg.

Voltage: 480/3/60 Hz (available transformer for 600 volt).

Spring loaded hold down rollers, preadjustable

in height,

Linked to main height adjustment.

Through feed by feed belt with variable speed 3-15m/

min by Gear motor 0,75kW.

Automatic centering of feed belt, pneumatically controlled.

Constant height of through feed, maximum height of Work piece 100mm.

Motorized height adjustment by gear motor 0,37kW

Digital display for showing height.

Control panel at left side.

Emergency off pull/push line at infeed and outfeed.

Emergency off by opened doors.

Connection for compressed air supply, 6 bar required.

Length x width x height (mm): 2500 x 1500 x 2100.

Motorized height adjustment of disc station including Digital display for disc station

The disc station is equipped by the following:

7 sanding discs in 2 rows, 250mm diameter, each with 24 Keyways 75mm long.

Excentric orbital disc movement (patent pending).

Gear motor 1,5 kW.

Variable disc speed 50-350rpm by frequency converter.

Separate manual height adjustment of the disc-station.

Selection switch for direction of discs.

Clockwise/counterclockwise (finer grit size/coarser grit size).

Spring loaded rubber covered hold down rollers before and behind each disc for holding down short work pieces without vacuum.

Counterrotating

rollers:

The counterrotating

rollers are comprised of the following:

· Spindles 90° to the feed, spindle diameter 50mm.

· Strong gear motors, 1,5 kW each.

· Variable spindle speed 100-500 rpm (for 300mm rollers) by frequency converter.

· First spindle turning with the feed, second spindle against the feed.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. Buyer is responsible to make sure all local regulations for installation and use are followed for area in which it is being installed. Govenment regulations may differ, depending on location.