2015 Brandt ***SOLD***KDF 440 Used Edgebander #BM2613

2015 Brandt ***SOLD***KDF 440 Used Edgebander #BM2613

Location:Uxbridge, Canada

Description

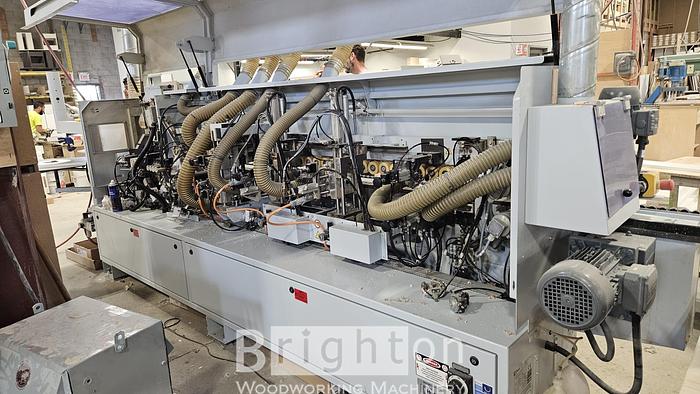

2015 Brandt KDF 440 Used Edgebander, with premill and corner rounding!

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information

Click <SHIP> for shipping information.

Specifications

| Manufacturer | Brandt |

| Model | ***SOLD***KDF 440 Used Edgebander |

| Year | 2015 |

| Condition | Used |

| Serial Number | 01-261-66-2108 |

| Stock Number | BM2613 |

| Quality | Very Good |

| Electrics | 600 V / 3 Ph / 60 Hz |

Additional Features

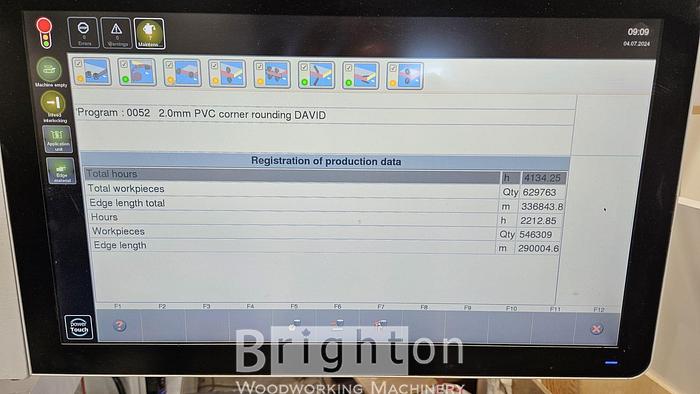

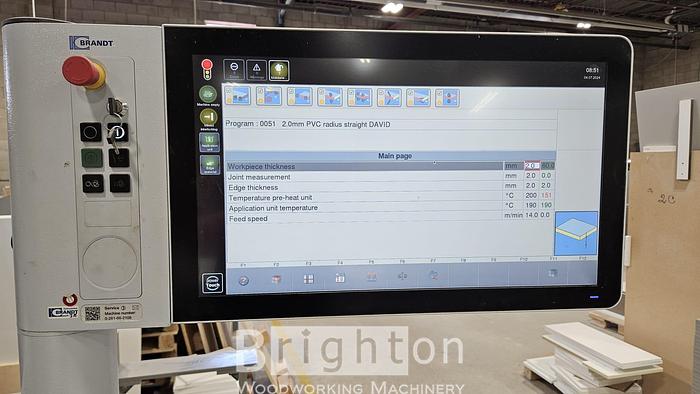

BRANDT - KDF-440C ... Edgebander (w/Pre-Milling & Corner Rounding, with HIGHFLEX Automated package: -- Edge & Workpiece Capacity:0.4 - 8 mm (0.016 - 5/16") edge; 8 - 60 mm (5/16 - 2-3/8") panel thickness; 160 mm (6-3/8") min. panel length and 70 mm (2-3/4") min. panel width.Equipped with: -- Pre-Milling Station, (2) motors @ 2.25 kW (3.0 HP), 12.000 RPM, LH & RH rotation w/pneumatic jump control for chip-free and clean panel edges. Equipped with diamond cutter heads -- In-feed Fence, with servo motor positioning. -- Infrared Radiant Quartz Heating Unit between glue roller and pressure section. -- Automatic Edge Magazine, for strip & coil stock, strips 0.4 mm - 8 mm (0.016 - 5/16"), coils up to 3 mm PVC and "HD" guillotine. -- "Quick Change" Glue Tank for maintenance & glue color change. -- Pressure Section, 1st. roller driven plus (3) idle rollers, timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover. -- Feed Speed, variable 8 - 14 MPM. (26 - 46 FPM), 11 MPM (36 FPM) when using contour trimming. -- BRANDT "Power Touch Control, Memory: 256 MB Ram, 1 GB Flash Card Drive, Operator control panel w/22" color HD wide screen, soft keypad & internal modem for remote diagnostic link.Workstations: -- End Trimming: -- (2) Motor @ 0.35 kW (1/2 HP) 12,000 RPM, automatic chamfer from control panel 0°- 15°. -- Flush/Bevel-Fine/Radius Trimming Unit: Top/bottom (2) motors, 0.55 kW (3/4 HP) 12,000 RPM, auto tilt postioning 0° - 25°, with combination flush/radius/chamfer cutterheads; horizontal and vertical tracing wheels, equipped with brushless multi-axis Servo motors for positioning of work-unit & horizontal copy wheels for quick changeover. Includes (3) positioning options, profile 1, profile 2, and flush trimming. -- Corner Rounding Unit:(1) Motor 0.35 kW (1/2 HP) 12,000 RPM for leading & trailing edges vertical corner rounding of panels; either radius or chamfer cutters can be mounted; 3 mm max. edge thickness. -- Scraping, Multi-Profile (PVC):Top/bottom with (2) profiles. 1 mm and 2 mm or 3 mm instead of 2 mm, servo control positioning of vertical & horizontal copy wheels. PVC scrape collection box. -- Scraping Glue Unit:Flush top/bottom on panel surface with floating insert knives. -- Buffing Unit: Top/bottom (2) motors, 0.10 kW (0.125 HP) 2,800 RPM. -- Riepe anti- adhesion. -- Riepe detergent. Complete with:Motorized, programmable hold-down pressure beam; padded sound enclosure, used tooling and Original Factory machine documentation. -- Actual Model is BRANDT, OPTIMAT KDF 440C (corner rounding).

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing. Buyer is responsible to make sure all local regulations for installation and use are followed for area in which it is being installed. Govenment regulations may differ, depending on location.