2013 Fravol ****SOLD***S600-23 used edgebander #BM2575

2013 Fravol ****SOLD***S600-23 used edgebander #BM2575

Location:Uxbridge, Canada

Description

2013 Fravol S600 used edgebander, with Premilling, IR lamp and Corner Rounding, plus plus

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information.

Click <SHIP> for shipping information.

Specifications

| Manufacturer | Fravol |

| Model | ****SOLD***S600-23 used edgebander |

| Year | 2013 |

| Condition | Used |

| Stock Number | BM2575 |

| Quality | Very Good |

| Electrics | 600V / 3Ph / 60 Hz with included transformer. |

Additional Features

Fully loaded Italian made edgebander with lots of really nice features including Corner rounding, Premilling, IR Lamp and many, many others.

• Edge & Workpiece Capacity: 0.4 - 8 mm (0.016 - 0.315") edge; 10 - 60 mm (0.394 - 2.362") panel thickness;

• 140 mm (5.512") min. panel length and 100 mm (3.937") min. panel width.

• Feed-speed, 14 or 18 MPM (46 or 59 FPM.)

Front-End Equipped With:

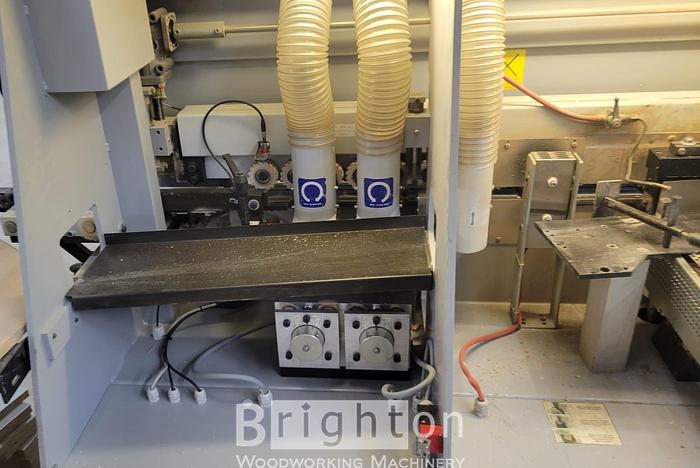

• Pre-Milling Station (RT/S), (2) motors @ 1.1 KW (1.5 HP), 12.000 RPM, LH & RH rotation w/pneumatic programmable jump control for chip-free and clean panel edges. Standard equipped with Dia. 60 mm x 64 mm H, with diamond inserts.

• IR Panel Heat Lamp: Improves gluing bond especially during cooler ambient temperatures and humid conditions.

• Automatic Edgemagazine: For strips up to 8 mm & coil stock up to 3 mm thick PVC.

• Duo Gluing System: For regular granulate Hot Melt (EVA) and easy conversion to PO glue. "Teflon lined" glue tank with bi-directional glue roller.

Automatic temperature reduction during stand-by time. Glue tank has quick release system for maintenance or quick change to different color or glue type.

• Side Pressure Section: (3) Pressure rollers, (1) motorized, (2) idle, pneumatic pressure control and programmable NC-positioning servo motor.

Work-stations:

• End Trimming (INT 2/S): (2) motor @ 0.50 KW (0.70 HP) 12,000 RPM, automatic pneumatic chamfer 0 - 15 or total exclusion from control panel. Glides 45 on prismatic linear hardened steel guides.

• Trimming Unit (RF-S/S): Top/Bottom flush/bevel/radius milling unit, (2) motors, 0.73 KW (1.00 HP) 12,000 RPM. Pneumatic remote tilt in (2) positions, postion-1 for radius and thin edges up to 0.8 mm trimming, position-2 for flush trimming up to 8 mm edges.

Equipped with banding thickness gauge block feature for quick and easy set-up/change over. Includes 1-axis nc servo control motors for programmable change-over from thin to 8 mm solid wood edges or incremental re-positioning of the cutter-head.

• Corner Rounding Unit (SYNCRO 1): Compact and easy to set-up for leading & trailing edges, (1) motor 0.22 KW (0.295 HP) 12.000 RPM, electronically synchronized. Working capacity, min. 10 mm, max. 60 mm panel thickness.

• Profile Scraping Unit (RB/S): Top & bottom radius scraping for PVC - ABS edges. Heavy construction to eliminate vibrations and guarantee superior edge quality. Air blow-off jets and chip collection box.

• Clean Spray System: Top/Bottom spray nozzles applies edge cleaning solvent prior to buffing.

• Glue Scraping Unit (RC/S): Top & bottom pneumatically operated glue scraping on flat panel surface to remove potential glue squeeze-out that otherwise would coat the cloth buffing discs.

• Buffing Station (GSI/S): Top/bottom (2) motors, 0.09 KW (0.125 HP) 2,800 RPM, manual, horizontal, vertical and tilting adjustment

• Hot Air Unit PHON (GP/S): Top/bottom hot air blowers to restore PVC color after scraping. Electrical power 2,000 Watt, 0 to 600 C temperature adjustment.

Complete With:

PLC Program Control, with 10.7" color touch screen display, can store up to (800) machining programs.

Graphical operator interphase for easy program input or manual operation of all workstations.

Motorized and programmable up/down hold-down pressure beam.

Sound enclosure with interior lights for convenient machine set-up or maintenance.

SMART S600 SINGLE

SIDED AUTOMATIC EDGE BANDER

SMART edgebander series were designed to be compact, versatile and userfriendly.

They have a rigid steel frame, with a top pressure beam with double rows of pressure wheels and top workstations

lifting

throughout. The displacement is read via a digital position indicator.

A conveyor belt;gliding on a flat, round profile is aligned with the top bar.

In order to ensure maximum precision, the belt is moved by a sturdy 1 1/2" (38.1 mm) chain that is driven by a 0.75 kW

right angle gearmotor. The feeding speed is 12.5 m/min.

The control panel is located in an easy to access,

practical position. This panel contains the controls to startup

the

machine and the PLC for machine management and optimisation.

The PLC has a monitor, which displays: feeding speed, glue pot temperature, and the program type selected by the operator. The spacing required between each panel is managed by the PLC by means of a Proximity Sensor.

The panel

is measured by fibre optic bar code in order to obtain the precise operations of each working group.

The glue pot located under the edgebanding feed table is lined with Teflon in order to make replacing and cleaning of the

glue as easy as possible.

The glue pot has 6 resistors which provide 3.6 kW of heating power.

The glue pot is moved horizontally at a 45° angle by a 25 mm wide prismatic guide.

Rolls of edgings up to a maximum thickness of 3 mm, with an Ø800 mm swivelling roll holder can be loaded

automatically

through the pneumatic positioning of the edging return.

The loading of edge stripsup to a maximum thickness of 8 mm, is standard with individual strips loading or the automatic

loading of strips (max 8mm) can be performed by adding the option no.5 (spike pin roller).

All motors are 12000 RPM / inverter controlled.

The machine has separate cabins for the gluing area and the working units both are viewable through windows. Also

included are door safety microswitches and a light for improved operator visibility in the machine enclosure.

Main shaving hood Ø 120 mm comes complete with the residue shaving hood and an intake vapor port hole locared

above the glue pot.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.