2012 Felder ***SOLD**Format 4 K400 X-Motion Used Sliding Table Saw #BM2549

2012 Felder ***SOLD**Format 4 K400 X-Motion Used Sliding Table Saw #BM2549

Location:Uxbridge, Canada

Description

2012 K400 X-Motion Used Sliding Table Saw - Auto Rip fence, blade height and angle from screen, 2 outriggers, digi crosscut and outrigger. (Compare New at $60,000)

See link to Felder listing for this machine when new...Felder K400 X-Motion Sliding Table Saw

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

Click <LEASE> for leasing information

Click <SHIP> for shipping information.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

| Manufacturer | Felder |

| Model | ***SOLD**Format 4 K400 X-Motion Used Sliding Table Saw |

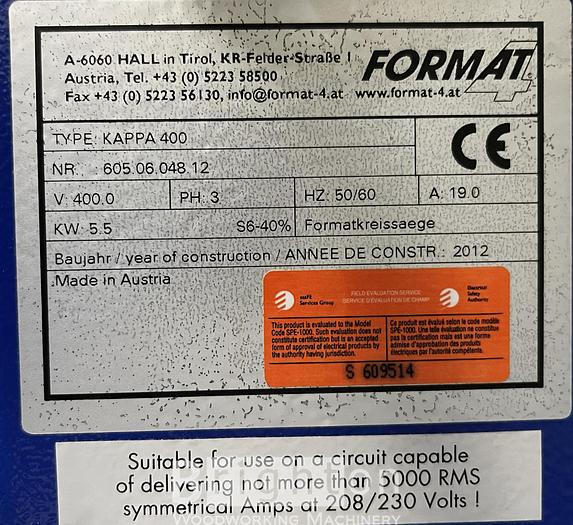

| Year | 2012 |

| Condition | Used |

| Serial Number | 605.06.048.12 |

| Stock Number | BM2549 |

| Quality | Very Good |

| Electrics | 400 volt / 3Ph / 60 Hz |

Additional Features

Cutting length: 2050-3700 mm "X-Roll" sliding table,

Rip capacity: 800-1500 mm

Cutting height: 133 mm

Control system: x-motion 9x99 program spaces + cutting sequences

Panel saw drive unit 133

• Electronic height adjustment with LED display

• Electronic angle adjustment with digital LED display

• Tilting of saw-blade 90°-45°

• Oversized saw arbor with double bearing trunnions

• Maximum energy transfer from the Poly-V belt

• 3-speed: 3500/4500/5500 rpm

• Optimal extraction with a completely enclosed, below table extraction system

• Dovetail guidance system of the height adjustment

• A highly robust synthetic material located in the guidance track of the tilting brackets,

ensures they run smoothly and are maintenance free even under the most extreme

conditions. The tilt guide segment runs without lubrication and is insensitive to dust.

“Easy-Glide”

• High precision double-sided trunnion support system

• High load-bearing capacity and operating life

• Play-free tilt

• Unaffected by dust

• Completely maintenance free

• No lubrication required

Tilting of saw-blade

• Tilting of saw-blade 0°-45°

• 133 mm of cutting depth at 90 degrees

• 94 mm of cutting height at 45 degrees

To use a grooving cutter “Dado cutter”

Slot cutting is possible with Format4 panel saws. The use of adjustable dado tools, specifically

developed by Format4, can be used thanks to the removable circular saw flange and the table

insert.

"Easy-Lock" tool free saw blade change

The clamping system is maintenance free and offers premium comfort for many years: Change

saw blades effortlessly in literally no time at all.

Simple, safe & quick - "Quick-Lock" saw blade clamping

An alternative to the worldwide unique Format4 saw blade quick change system "Easy-Lock" is

now the "Quick-Lock" clamping system, which with the use of just one tool makes it quick and

easy to change the saw blade.

Positioning control of the rip fence

The rip fence is positioned by a motor and runs via a dust-free integrated ball spindle in the saw

table. Fence positioning is accurate to 0.1 mm, this combined with fast positioning speed and

that the saw blade height and tilt can be adjusted simultaneously, ensures precision and

significant reduction in working time.

• Automatic measurement correction when the rip fence is laid flat

• Rip fence park position

• No collision possible with the saw blade due to the coordination of the tool database by the

positioning control

• The rip fence can be swung away at any point along the full rip capacity

“X-Roll” outrigger table

The 8x ball bearings, integrated guide rollers and bearings of the outrigger table ensure an

incredibly smooth operation upon maximum loading capacity. The support rail is moved along

an “X-Roll” guiding system and is fast and fine-adjustable. The LED display enables you to set

the required angle to one tenth of a degree. The fence can be tilted to any position between -45°

and +45° and guarantees precise mitre cuts.

Main operating switches on sliding table

As an option, it is also possible to equip the saw with the wireless push button control “ON”

switch of the main blade and scoring blade to the sliding table, speeding up the work process

further.

“X-Roll” sliding table

“X-Roll”, making a difference:

• Extremely smooth and precise sliding action! With the roller-bearing system there is no

single point of contact between bearings and guiding track, maximising precision over

the lifetime of the machine. A 3 way dust protection system ensures clean, dust free

guide rails. This is obtained through silicon wipers, brushes and concave tracks.

• Clean, dust-free guide rails thanks to special silicon wipers.

• Hardened-steel tracks ensure accuracy and durability.

Parallelogram outrigger table

The solidly built parallelogram outrigger table enables mitre cuts from –45° to +45°. The surface

available for the workpiece remains the same regardless of the angle setting. The digital display

of the angle setting is accurate to 1/100th of a degree. The angle/length compensation is

carried out using either a Nonius scale or “digi-compensation plus”.

Angle adjustment and fence length compensation:

No reading errors due to scales and vernier. No time-wasting with arduous approximations of

angle values. The advantage of the FORMAT-4 degree index is that the stop is set and fixed

without losing time or making reading errors.

Outrigger table

The outrigger table with workpiece roller is large in its design and the eight ball bearing guide

rollers in the support arm ensure an extremely smooth movement, even when under maximum

load.

Telescopic crosscut fence

The telescopic fence enables crosscuts of up to 3200 mm. Top class engineering and ease of use

are features which are a part of the standard equipment. The scale and the magnifying glass on

the stop ensures precise adjustments and settings from the operating area.

Digital accuracy

On request, we will equip your Format4 with the digital telescopic fence. Below, you see the

cleverly integrated electronic digital scale with values correct to 0.1 millimeter. Additional

functions, for example the setting of successive measurements, make your daily working life

easier.

Swing away overhead saw guard

The overhead saw guard is height adjustable and can be swung away. The average depth for

especially wide work-pieces is 608 mm.

Always at hand - Additional storage options in the front tool compartment

The tried and tested tool compartment positioned directly at the front of the machine has now

been made even more practical with the addition of two magnets for the storage of the riving

knife and the scoring blade. There will also be the possibility to attach the edging shoe directly

to the machine for storage. So, everything is always in its place!

Spraying equipment for the processing of non-ferrous metals and plastics

Your Format4 can be optionally fitted with a spraying unit. High performance lubricating oil can

be sprayed directly onto the saw blade, transported via piping from the spraying unit.

kappa 400 x-motion

The kappa 400 has the option of a scoring unit with 2 controllable axes:

• The vertical and horizontal position of the scoring blade in relation to the main blade can

easily be set from the control panel

• The information relating to the scoring blade can be saved in the tooling database

appropriate to the saw blade. The next time the saw blade is required, the scoring blade

automatically positions itself appropriate to that saw blade.

kappa “x-motion”: Standard

CNC-drive control unit with 5.7” (145 mm) TFT screen situated in the overhead control panel

functions

• Positioning control of the saw blade height

• Positioning control of the saw blade angle

• Automatic cutting depth compensation when tilted

• Saw speed display

• All possible functions also available in touch control mode

• 99 storage locations in the tool database

• 9x 99 storage locations for cutting programs

• Program with stored functions (grooves, row of grooves, rabbets, wrong mitre, mitred cuts,

calculator)

“digi-compensation plus” - digital angle/length compensation

The digital angle and length compensation module "digi-compensation plus" for X-roll or

parallelogram outrigger tables compensate any changes in the length difference of the crosscut

fence settings, as the angle is changed. The direct communication with the controls, also

enables it to compensate the fence position of the crosscut stop to the width of the tooth and

the tilt of the saw blade. This ensures that you always get an exact measurement without any

recalibration when using different saw blades.