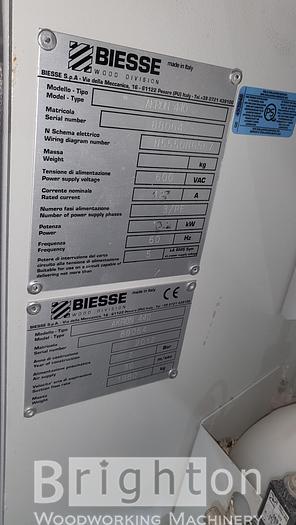

2012 Biesse Artech Akron 440 Automatic Edgebander #BM2399

2012 Biesse Artech Akron 440 Automatic Edgebander #BM2399

Location:Uxbridge, Canada

Description

2012 Biesse Artech Akron 440 Automatic Edgebander. Servo driven.

Click INSTANT PRICE anywhere you see it on our site to receive an instant auto-quote, with Pricing and Specs, directly to your email!!

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

For leasing info call Lindsay at 905-758-0797 (mention Brighton Woodworking Machinery and BM# of machine)

For shipping quote, call Katharine at 905-663-2881 (mention Brighton Woodworking Machinery and BM# of machine)

Specifications

| Manufacturer | Biesse |

| Model | Artech Akron 440 Automatic Edgebander |

| Year | 2012 |

| Condition | Used |

| Stock Number | BM2399 |

| Quality | Very Good |

| Electrics | 600V / 3Ph / 60 Hz |

Shipping details

| Weight | 1980 kg |

Additional Features

Why have someone under your hood messing with things when you don't need them there!

Change overs are a breeze with this machine. Simply select the program and the settings are adjusted for you.

Description

One-sided edge banding machine for the gluing and post-processing of edge material on panel-shaped workpieces using synthetic resin hot-melt adhesives and polyurethane adhesives.

With 2 glue containers for EVA glue and 1 glue container for PU

Granules. There is also a nitrogen storage box for the PU glue pot.

Control System:

TS 10 NC control with 10 inch touch panel

WINDOWS CE operating system

Technical specifications:

Workpiece thickness 10 - 60 mm

Workpiece thickness with MFU unit

Workpiece thickness: from 10 to 60 mm

Workpiece thickness with MFU unit: from 10 to 35/60 mm (profile dependent)

Edge height: from 14 to 64 mm

Edge thickness rolled goods: from 0.4 to 3 mm

Edge thickness strip material (*): from 0.4 to 10 (12) mm

Workpiece projection: 25 mm

Minimum board length: 140 mm

Minimum width (at 140mm length): 85 mm

Minimum width (at 250mm length): 50 mm

Feed speed: 18 m/min, 12 m/min. when copying corners

MACHINE EQUIPMENT:

Axis-controlled infeed fence

ANTI-STICK-SOLVENT APPLICATION

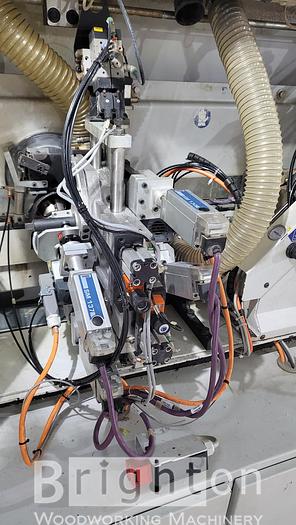

JOINING MILLING UNIT AT THE INLET FI-502

Motors a 3.5 KW

The AUTO-SET device: ensures optimal positioning of the cutters, depending on the thickness of the piece to be machined. Vertical movement of the two motors on linear guide elements

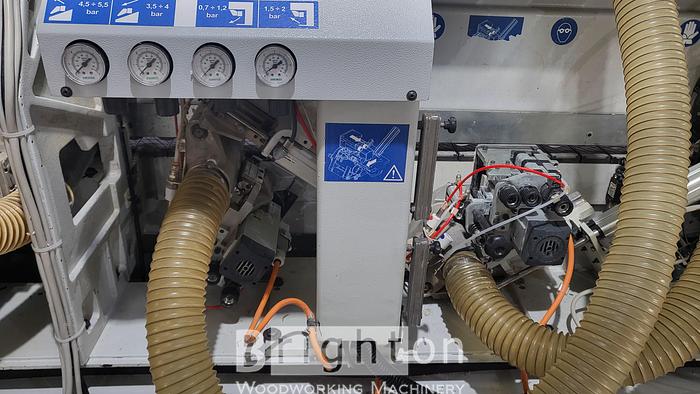

GLUEING UNIT VC-511

With option KIT PRO-GLUE

The PRO-GLU kit consists of the following components:

• System TEKNO-GLUE for optimal gluing through:

- Controlled touch of the glue roller

- Automatic giving away at feed stop

- automatic ON/OFF of the gluing part

• REVERSE system to close the glue roller in the same or opposite direction

Dual gluing system using EVA glue and

POLYURETHANE glue in granular form.

This version makes the machine ALTERNATIVELY suitable for POLYURETHANE and EVA glue.

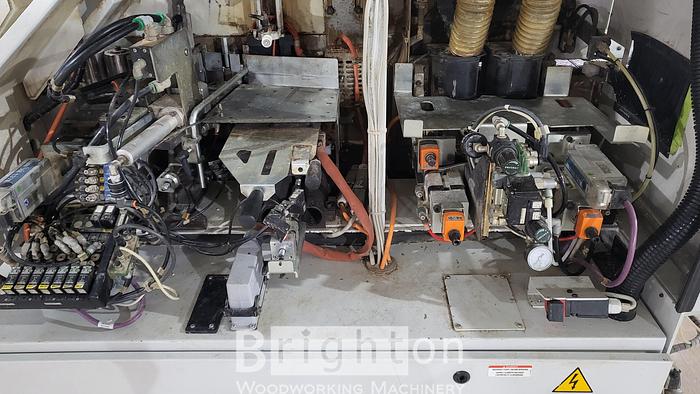

CUTTING UNIT IN-801

With System FLEX with controlled overhang. Allows adjustment of the saw blade trimming position via the control panel to obtain a specific overhang of the edge.

Gf0d3s9

FLUSH CUTTING UNIT BOTTOM and TOP RS-502

With DUO-SYSTEM: pneumatic control via NC which enables 2 different milling settings for flush milling. Also includes pneumatic emergence.

2 MOTOR MULTIFUNCTIONAL FORMING UNIT CR-200V

With SYSTEM FAST 4: Electro-pneumatic adjustment of the side touch on 4 fixed points.

PROFILE SCRAPING UNIT RBK

For reworking thick edges made of PVC/ABS.

With air nozzles on the feeler rollers as standard.

Manual removal of the unit from the processing line.

FLAT SCRAPER RCC-701

Scraper to remove leaked glue along the

glue joint.

BUFFER UNIT SP-501

Pivoting unit with automatic adjustment to the

Workpiece height, for cleaning and buffing the workpiece edge.

With fabric polishing discs. Two 0.37 kW motors. 2800 rpm.

HOT AIR BLOWERS

Allows high gloss colour and shine to return after the scrapping unit.

weight : 1980 kg