2023 BH Engineering 1325T4 Economical (NEW) CNC machining center #NBM2385

2023 BH Engineering 1325T4 Economical (NEW) CNC machining center #NBM2385

Location:Canada

Description

NEW BH Engineering 1325T4 Economical CNC machining center

- Designed for making cabinets

- Double spindle, cutting and grooving, saving tool change time and super efficient

- 9 Drilling rows. Automatically calculate and drill holes

- Included tool holders

- High-power single vacuum pump to meet the needs of cutting materials

- Efficient dust removal system

- User friendly software and free training

- 4'x8' work area

- One year warranty

For pricing please click “REQUEST QUOTE” wherever you see it on our Brighton Woodworking Machinery website at www.brightonmachines.com.

Click <LEASE> for leasing information.

Click <SHIP> for shipping information.

* All Descriptions, Specifications and Features are correct to the best of our knowledge. Interested buyers should verify before purchasing.

Specifications

| Manufacturer | BH Engineering |

| Model | 1325T4 Economical (NEW) CNC machining center |

| Year | 2023 |

| Condition | New |

| Stock Number | NBM2385 |

| Quality | Very Good |

| Electrics | 220V / 1Ph / 60 Hz |

Additional Features

Weighted bed structure (welded structure, heat-treated bed)

• The heavy-duty structure design is adopted, and the material stress analysis and tempering vibration aging treatment are used to make the machine precision permanent without deformation.

• The base is completed by CNC gantry five-sided integrated processing to ensure all the corresponding geometric tolerance standards of the body.

Matrix vacuum adsorption table (anti-fold + PVC sheet)

• It is made of PVC sheet, which is wear-resistant, fire-resistant and never deformed.

• The multi-purpose matrix design can cooperate with the mobile vacuum suction cup to process the workpiece.

• The special arc groove design can prevent the rubber foam sponge from falling off and causing vacuum leakage.

Gantry (High Performance Design)

• Welded, stress relieved and precision machined steel plates up to 8mm thick.

• High vertical precision and stable operation.

Gantry slides (high strength, good verticality, long life)

• It is precisely machined from cast iron tooling plate, and adopts five-axis horizontal machining center to ensure verticality.

• Cast iron brackets provide vibration damping properties while providing rigid support for the gantry tubes.

• The unique dust-proof design of the linear slide can still travel unimpeded in the harshest environments.

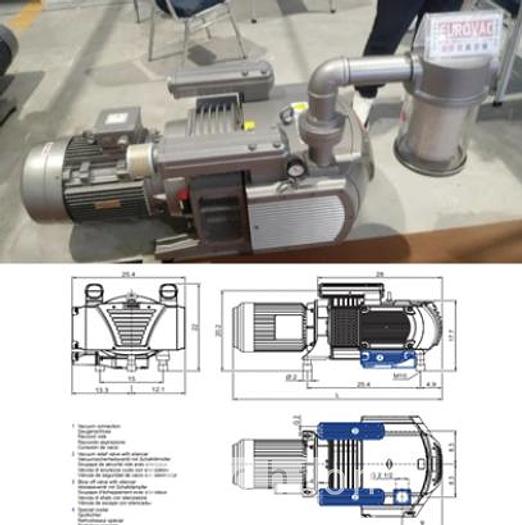

High-performance vacuum pump*2 (10 horsepower each)

• High-strength suction*2 to ensure the adsorption of various plates and small workpieces.

• Vacuum adsorption, long-term non-deformation, to ensure large adsorption force.

Air-cooled dual-spindle (0-24000rpm)

• High rotational speed significantly improves production quality and increases tool life at the same time.

• Slotting and cutting, saving tool change time and improving cutting efficiency

• Quick automatic tool change to ensure accurate clamping of tools.

• The unique dust-proof design of the linear slides can still travel unimpeded in the harshest environments

Drill row (efficient and versatile)

• Automatically generate laminate holes, saving calculation troubles.

• Automatically punch screw holes for easy installation.

• Replaceable drill bits to meet different sizes.

Automatic lube oil pump (adjustable refueling time and interval)

• Automatically inject lubricating oil into the required parts of the machine to ensure the smooth operation of the machine.

• Increase machine life.

• Save labor costs.

Tool setting instrument (automatic tool setting)

• Automatic tool setting, eliminating tedious steps such as tool change and parameter adjustment.

• Accurate and fast, greatly reducing errors.

Dust removal system (equipped with high horsepower dust removal motor)

• High horsepower dust removal motor to reduce the impact of dust.

• Double dust bag, double capacity.

Console (full-featured, movable)

• Quick functions such as emergency stop, start, pause, etc.

• The operating system is easy to learn and easy to operate.

• Handwheel simulation, safety testing.

Packaging (double insurance inside and outside the package)

• The whole body is fixed with wooden frame to avoid shaking and bumping.

• All-in-one package saves installation time.

Industry Applications:

1. Woodworking industry: three-dimensional wave board processing, processing of wooden doors, screens, craft fan windows, auxiliary processing of various furniture products

2. Advertising industry: advertising signs, logo production, acrylic cutting, blister molding, production of advertising products of various materials.

3. Mold industry: It can engrave metal molds such as copper, aluminum, iron, etc., as well as non-metal molds such as marble, plastic plates, and wooden boards.

4. Other industries: It can engrave various reliefs and is widely used in the craft gift industry.